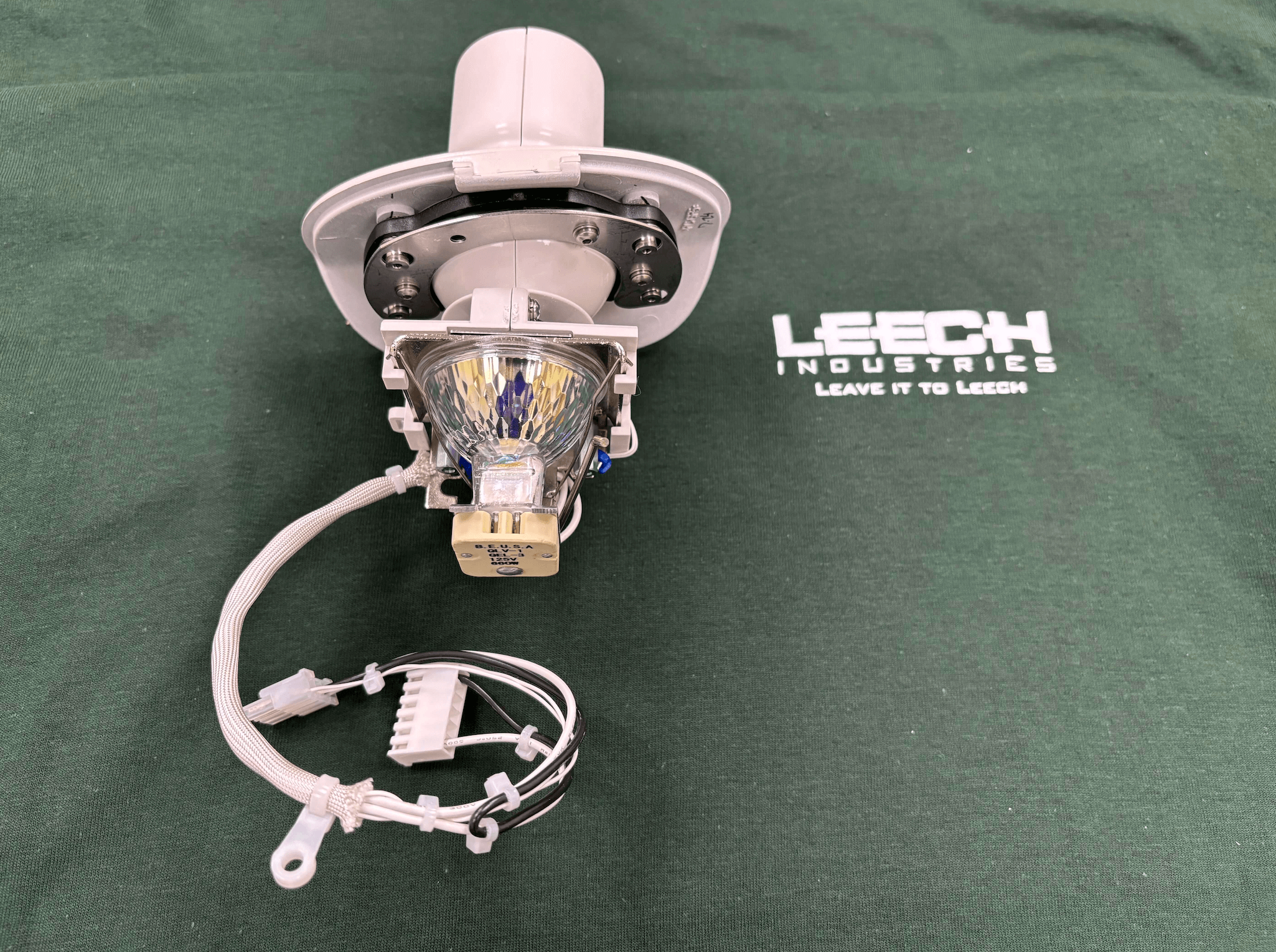

Engineering has finished designing a new product. Sales and marketing is excited to launch it to the market. Now is the time to move it into production. The question for the production team is do we make or buy? Looking at the finished product, this seems easy.

But as the full scope comes clear, the complexity of the make buy decision moves from one item to dozens or more.

Managing the analysis and decisions on sources of parts, assembly levels and final assembly can quickly become overwhelming when it comes to producing complex assemblies. In contrast, sourcing your entire assembly from a single source can simplify your supply chain, reduce risks, and ensure all components fit and function as required.

Sourcing your finished assembly from a single, quality Precision Manufacturer can deliver your assembly to market faster, at lower total cost, and at a lower overall logistical strain on the product’s owner. As companies make this decision, here are some of the benefits in sourcing your product assembly from a single source.

Design for Manufacture

A key step in moving from final product design to manufacturing is the design for manufacture step. Partnering with a company that has engineering capability of its own can streamline this process and create confidence that your design will be produced as conceived. This includes looking at assembly and component level requirements, process steps in the component manufacturing, and process steps in the assembly manufacturing. A supplier with the engineering capability to develop the manufacturing process and directly interact with the production floor at all stages from process development through first part and assembly run, PPAP to volume production is a key partner to have.

Streamlined Supply Chain

When sourcing your assembly from one supplier, you can significantly streamline and simplify your supply chain. Leveraging our one-stop contract manufacturing services means allowing Leech Industries to handle everything from sourcing or manufacturing internally individual components to assembling the final product. This eliminates the need to manage multiple suppliers, saving time and reducing the potential for delays caused by coordinating with multiple manufacturers. The Product Owner can spend more time developing its next product or marketing of the existing product while Leech Industries shepherds the manufacturing process.

Timeliness

In today’s competitive marketplace, time to market is critical to a product’s success. Whether a new product, an innovation to an existing product or just dealing with sustaining the product, time to market is enhanced by partnering with strong one-stop contract manufacturing services since their resources add to and compliment your own. When the Leech Industries’ team manages the entire assembly, we control the timeline from start to finish. This puts us in the driver’s seat so we can address any opportunities or challenges promptly and deliver on time. By handling all components and their necessary timelines, we can more accurately coordinate to ensure on time delivery at exceptional quality.

Simplified Communication

When you opt to work with one shop for production and assembly, you only need to make one call for status or change coordination. There’s no need to navigate multiple layers of suppliers, as Leech Industries takes full responsibility for the entire assembly, ensuring a smooth process from start to finish.

Reduced Risk

Every supplier you add into your assembly introduces another opportunity for risk. With every handoff, something can fall through the cracks, resulting in miscommunication, delays, or quality issues. By consolidating your assembly needs with Leech, you minimize risks and streamline operations.

Additionally, if problems arise in a multi-vendor setup, there’s often a complex analysis required to identify the source and develop a timely solution. By sourcing everything through Leech Industries, we take on full accountability. If there’s a fit, function or quality issue, it’s our job to resolve – not yours. Handing off responsibility to our team can save you time, frustration, money and end user confidence, allowing you to focus on other pressing matters.

Guaranteed Quality

When our team handles the full assembly process, Leech Industries controls the quality assessment of all components at all stages of production. This allows us to catch and correct issues right away, ensuring that the final product meets all customer specifications.

We understand the critical importance of managing tolerance stack-ups, which can occur when individual tolerances combine to create out-of-spec final products. When we manage production in-house, our skilled team can make adjustments as needed to ensure high-quality results every time.

Reduced Complexity and Logistics

Sourcing your assembly from a one-stop contract manufacturer simplifies procurement and reduces the logistical headache that comes with managing multiple suppliers. The Leech team handles everything from tracking lead times to managing outside vendors for any additional processing that may be required. This means less work for you and a more streamlined procurement process overall.

Why You Should Count on Leech Industries’ Assembly Services

When we touch base with OEMs, we hear a common concern associated with sourcing their entire assembly from one shop: the risk of putting all their eggs in one basket. What happens if the shop you’ve come to rely upon can’t be relied upon?

By partnering with Leech Industries, customers can feel confident that they’re putting their parts in capable, expert hands. Leech Industries track record of success in providing reliable assembly services to a wide range of industries began in 1948 and continues through today.

Whether you need an assembly of two parts or 2,000 parts, our team has the capacity and capability to handle your needs. Our recent shop renovations – focused on making the layout of our shop more “Lean” – have expanded our assembly area, allowing us to take on complex projects with even more confidence.

Let us be your one-stop solution for all your assembly needs. Request a quote today to experience the peace of mind that comes with leaving it to Leech!