At Leech Industries, we’re committed to staying on the cutting edge, especially for challenging industries that require flexibility and high precision.

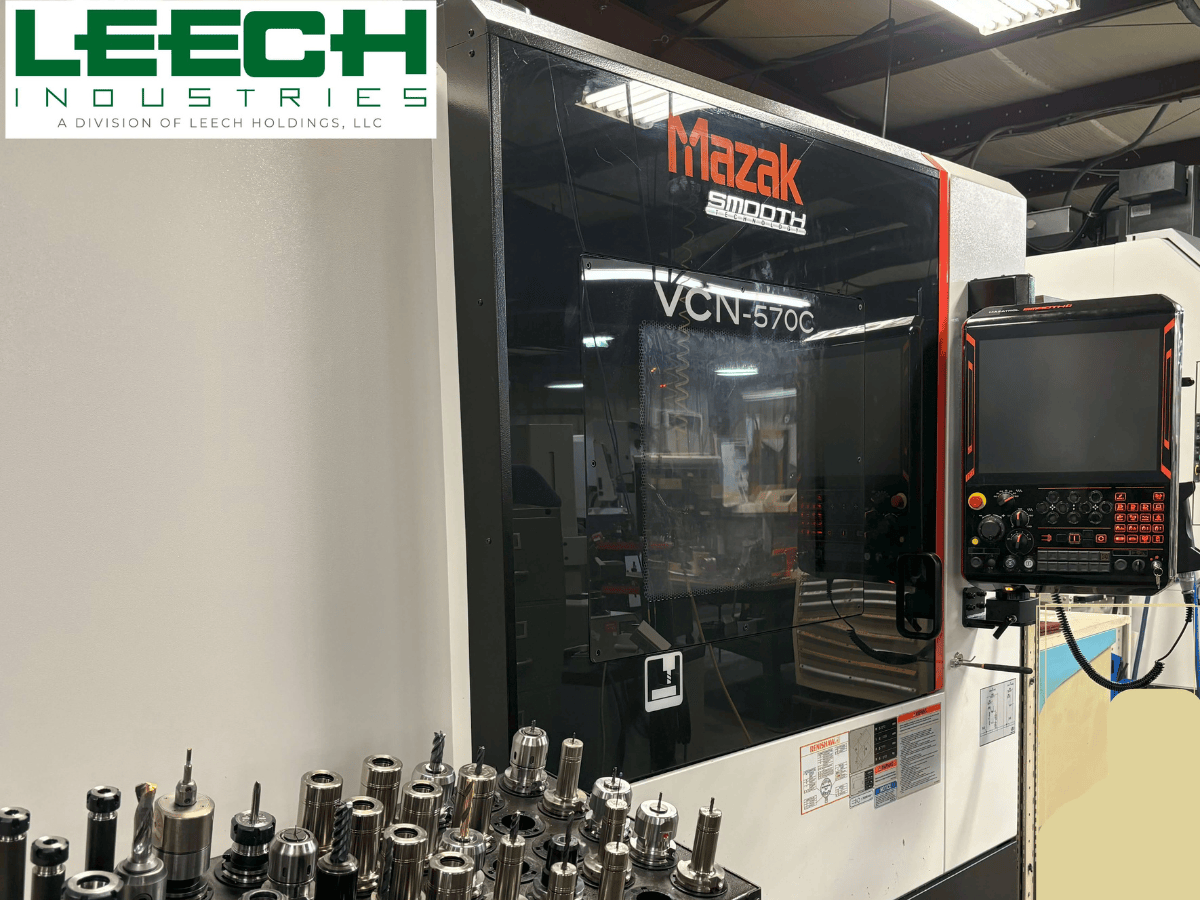

Earlier this year, our team invested in a second 9-axis CNC machining center to meet the growing volume of high-complexity work in the aerospace and defense sectors. This machine adds to our growing fleet of highly capable multi-axis machines. With fully robotic, lights-out machining capabilities, this advanced equipment allows us to produce parts efficiently around the clock without constant supervision. This powerhouse tool supports our ability to meet our customers’ requirements, such as complex assemblies and multi-part production runs.

Our Specialty: Low-Volume, High-Mix

Here at Leech Industries, our Precision Machining team specializes in low-volume, high-mix manufacturing, creating highly tailored solutions that meet the quality, cost and schedule of our aerospace/defense customers. Our team will guide your part through each stage beginning with a project kickoff, followed by project planning, production, quality verification, and delivery. Each step is monitored and understood to ensure we meet your cost, quality and schedule needs.

Our CNC machining processes are designed to accommodate projects requiring frequent switching between jobs with minimal setups. This efficiency is key to reducing errors and maximizing quality. Leech Industries multi-axis machining capabilities allow us to handle these transitions seamlessly, reducing downtime and increasing output.

Whether it’s a complex single piece, with tight tolerances or a limited production run of the same complex part, Leech Industries has the machines, tools and expertise suited to the job.

We Machine Exotic Materials

The aerospace and defense sector have rigorous requirements that often lead to the use of harder to machine materials. These include materials such as titanium, inconel, beryllium copper, and specialty forgings of more common materials. These materials require additional knowledge by the machinist and tooling specifically designed to machine exotic metals. In addition, the machines themselves benefit from high pressure coolant capability, heavier horsepower and the increased software tools. Leech Industries has made and continues to make investments in all facets of exotic material machining.

Meeting Exacting Standards

Leech Industries has a history of producing parts that meet the most exacting standards in the aerospace and defense sectors, where precision is non-negotiable. Our ability to hold extremely tight tolerances down to 2 tenths on the machine and to 0.5 tenth or better with post processing grinding ensures that every part we deliver meets the necessary specifications.

As an ITAR-compliant manufacturer holding both ISO 9001 and AS 9100 quality certifications, Leech Industries is qualified to work alongside Tier 1 suppliers, as well as the U.S. government. We have our ducks in a row regarding certifications and quality control procedures so we can meet all regulatory requirements, thus positioning us as a trusted partner for aerospace and defense projects.

![leech mazak 1]() A Proven Track Record in Aerospace and Defense Manufacturing

A Proven Track Record in Aerospace and Defense Manufacturing

Our expertise in CNC machining enables us to run essential components for aerospace applications. We produce parts for the International Space Station, including urine tanks for NASA’s Orion Crew Survival System (OCSS). In the defense sector, Leech Industries manufactures components for the F-104 engine, MK48 Torpedo System, and specialized assemblies and components for a variety of weapons systems. We’re experts in producing components designed to perform in harsh environments where precision and reliability are essential.

Looking for a Trusted Aerospace and Defense Supplier?

From aircraft components to defense systems, we’re equipped to meet the exacting standards required by the aerospace and defense industries. Our commitment to delivering the highest-quality CNC machining services is reinforced by ongoing investments in top-of-the-line equipment and the continuous advancement of our team’s expertise. We’re proud to contribute to the competitiveness of American manufacturing by harnessing advanced technology like our 5 and 9-axis machines to support your critical applications.

Are you seeking a reliable, cutting-edge supplier for your aerospace and defense components? Look no further. Request a quote from Leech Industries.

A Proven Track Record in Aerospace and Defense Manufacturing

A Proven Track Record in Aerospace and Defense Manufacturing