Over the past few months, our team has been challenged to find unique manufacturing solutions for companies from several industry sectors. These challenges range from field problems with product leakage to unreliable suppliers to improper assembly fits. Each case presents its own complexities, often involving multiple manufacturing processes and intricate design considerations.

Many of these challenges stem from a fragmented approach to manufacturing, where different components are produced by separate manufacturers and assembled elsewhere. This disjointed process can create communication gaps and reliability issues in the final product – not to mention longer lead times!

But we have a saying here: “Leave it to Leech.” Leech Industries has positioned itself as a one-stop shop for turnkey manufacturing solutions. Let’s explore how our unique approach solves intricate challenges and brings unparalleled value to our customers.

Comprehensive Turnkey Solutions from Leech Industries

In-House Capabilities

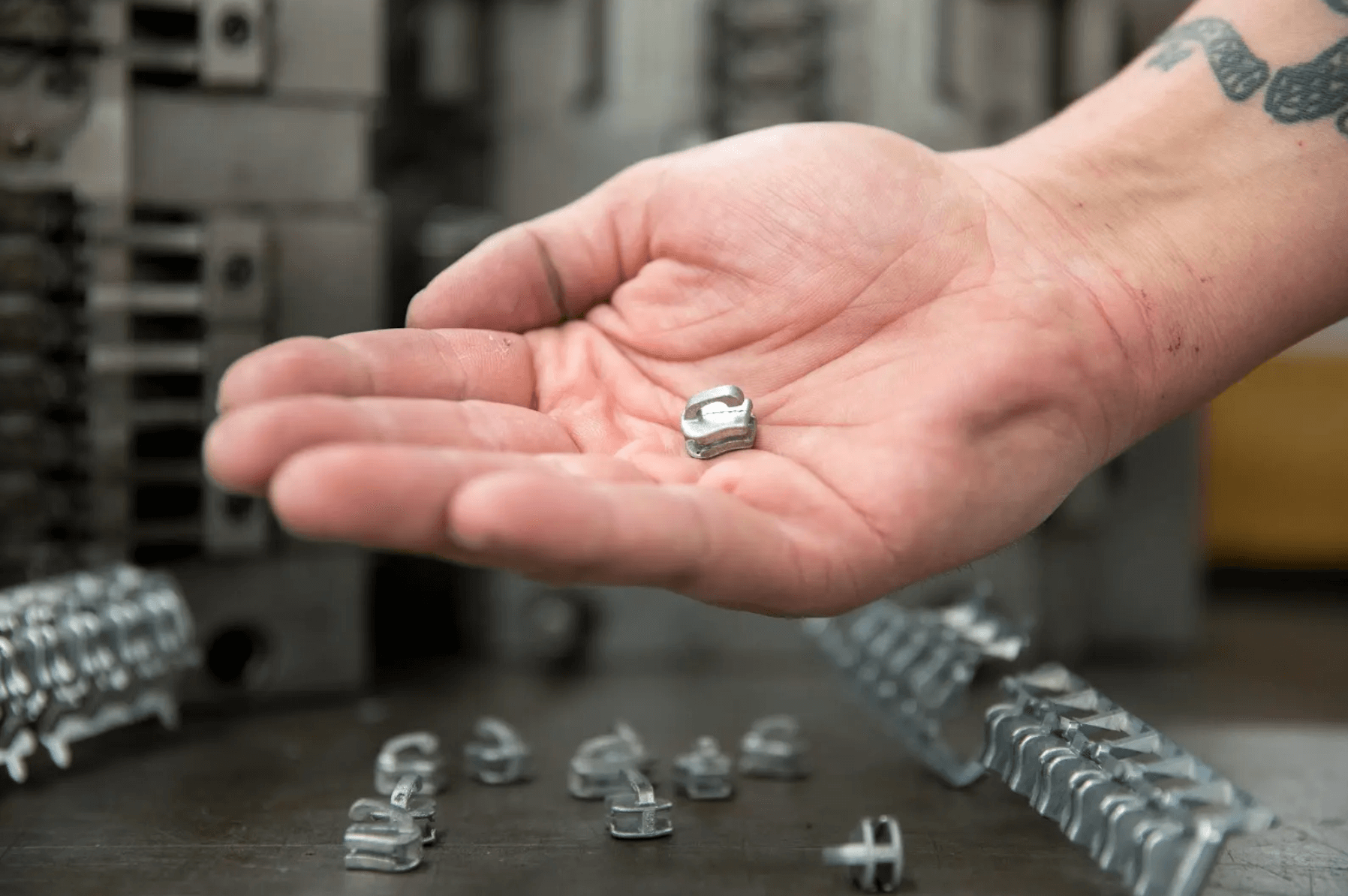

What sets us apart is our ability to handle multiple steps of the manufacturing process under one roof. From plastic molding, zinc die casting, progressive metal stamping and CNC machining to final assembly, we offer comprehensive, one-stop contract manufacturing solutions.

Collaborative Problem-Solving

With experts in all manufacturing capabilities within the four walls of our facilities, Leech Industries brings together individuals from various disciplines to solve problems collaboratively. Having the ability to internally huddle allows us to quickly identify issues and develop innovative solutions that might be overlooked in a more fragmented manufacturing process.

Design for Manufacturability (DFM)

We apply DFM principles not only to the final product but also to the tools and processes used in our services. As a result, every aspect of production is optimized for efficiency, repeatability, and quality.

The Benefits of Our Turnkey Approach

Faster Time to Market

Handling all aspects of the manufacturing process reduces the time it takes to bring a product to market. Due to our streamlined approach, we’ve been able to deliver results weeks earlier than anticipated in some instances.

Simplified Supply Chain

Customers can place a single purchase order with us. From there, we handle all the individual procurement and necessary coordination. As a result, we can simplify our customers’ supply chain significantly, reducing complexity and minimizing the headache that comes with juggling multiple suppliers.

Flexibility and Problem-Solving

Our diverse in-house capabilities offer us the flexibility to tackle unforeseen challenges quickly. We can bring experts from different disciplines together in minutes to develop solutions, which would be virtually impossible in a fragmented manufacturing environment.

Leverage Our Turnkey Solutions

In today’s market, where speed to market and product reliability are critical, our turnkey solutions offer a competitive edge. By bringing diverse manufacturing capabilities under one roof and fostering a culture of collaborative problem-solving, we can tackle complex manufacturing challenges. Whether optimizing an existing product or introducing a new part number, Leech’s comprehensive approach considers and optimizes every step of the manufacturing process.

Request a quote to experience turnkey component manufacturing services.