Leech is a design-build-run service providing cost-saving manufacturing to customers. By utilizing single-source options, we minimize handling while maximizing efficiency, accuracy and savings. From design to a completely finished product, you can rely on Leech Industries to meet your special requirements.

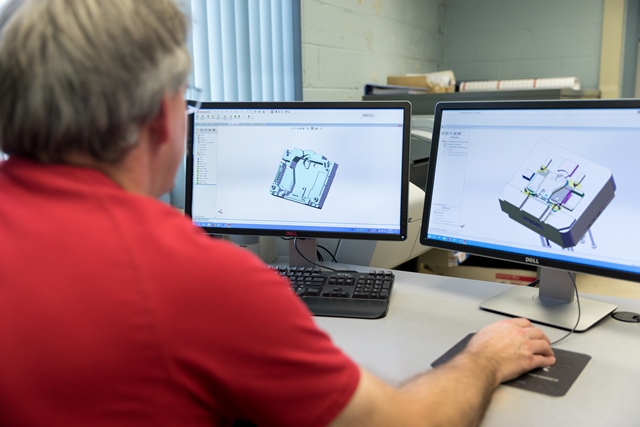

Our customer base is diverse when it comes to our design and engineering services. Some of our customers supply us with very specific details, including both 2D and 3D models. Other customers come to us with a hand-drawn sketch or even an idea in their head about what they’d like their part to look like. No matter how much information our customers provide, the engineering team at Leech is eager to support customers’ needs.

At Leech Industries, we specialize in turning your engineering drawings and specifications into high-quality, ready-to-use parts. Our skilled team of engineers and machinists meticulously follow your provided designs, ensuring strict adherence to tolerances, materials and finishing requirements.

We offer a prototype service to assist in product design evaluation and to aid in verifying manufacturing process capability. It is just a feature of our robust turnkey services, which support OEMs from prototype to production.

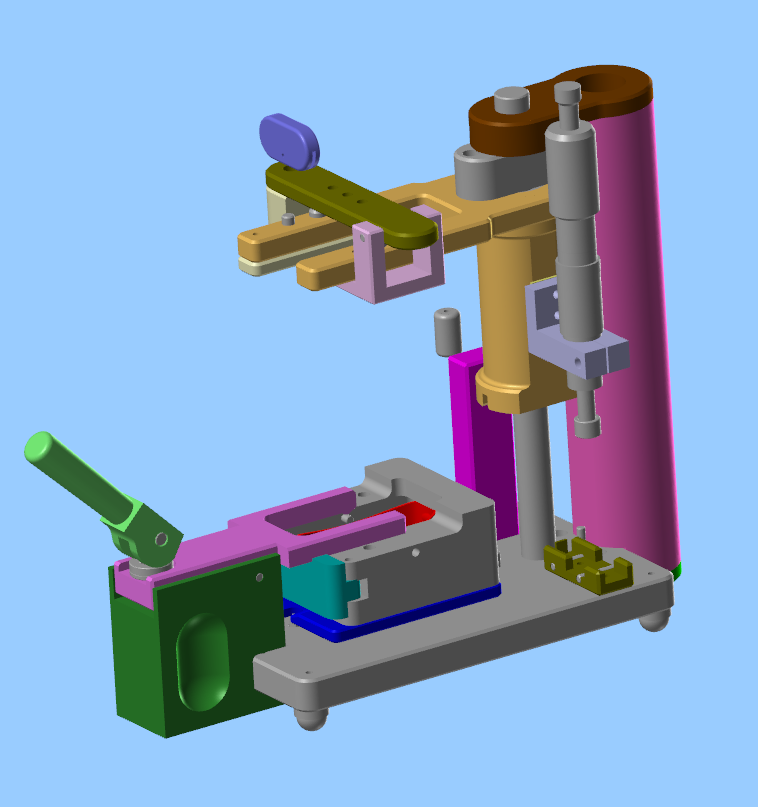

Equipped with the most efficient technology, we can quickly provide exacting designs for the highest quality precision tooling, dies and molds to customer specifications. For even greater flexibility, Leech provides file transfer and translation capabilities, enabling system compatibility, increased accuracy and/or further enhancement. Our goal is to get you exactly what you need within the time frame you need it.

Below is a comprehensive list of the CAD and CAM software we utilize, and how we use each:

Inventor deals most closely with 3D models of parts. It is important in our assembly process, as it develops virtual assemblies of multiple parts to detect interferences, ensure proper assembly and help us understand how different components fit together and interact. Its simulation tools allow us to test the performance and behavior of parts in assemblies, identifying potential issues and areas we can improve the design before we begin physical production. This provides us the tools we need to think proactively about our designs, so we can produce defect-free parts with greater efficiency and quality.

Our highly sophisticated quoting platform allows us to respond to requests for quotes with greater efficiency, accuracy and speed. Additionally, the platform supports our quality control team by flagging and assessing potential risks before we begin production. Paperless Parts enables Lean manufacturing principles by optimizing material usage, reducing waste and saving on material costs.

This comprehensive CAD software creates precise 3D models, assesses design viability, enables seamless collaboration and ensures accurate parametric designs. SolidWorks’ integrated CAM tools enhance machining and fabrication processes and result in increased accuracy, reduced errors and enhanced efficiency.

Autodesk’s AutoCAD software allows us to create detailed 2D drawings and part schematics, while clearly and accurately defining the specifications and dimensions of each part. Additionally, it can convert and modernize legacy drawings to make them more accessible and editable on our end.

MasterCam offers advanced CNC programming, 3D modeling and customization options that enhance productivity, precision and efficiency during production. The advanced toolpath feature helps us reduce machining time and cut down on production costs, resulting in time and cost savings for our customers.

For either 2D drawings or 3D solid models, we accept CAD/CAM files in the following formats:

Other file formats we can utilize: