Leech Industries’ zinc die casting process is cost-effective, dependable and crucial in applications across a scope of industries. Our talented team can deliver die-cast parts with the following properties:

Leech specializes in zinc die casting complex precision components that range from small to large in size. With the ability to apply secondary operations and plating on zinc die cast parts, we can maintain top-notch quality while reducing lead times and managing costs.

At Leech, we specialize in serving as a “one-stop shop” for your zinc die casting needs. With an in-house team of experts, we offer mold design engineering services, complete mold builds and mold maintenance. On top of handling any molding needs, we also maintain capacity for both prototype and full production runs in our die casting department. This gives us the ability to turn your ideas into as many zinc die cast components as necessary.

Leech Industries works with customers to turn their part concepts into full production runs. We maintain an open line of communication during the prototyping phase to ensure prototypes meet our customers’ design requirements before we produce parts at volume.

We implemented our turnkey solutions to simplify the customer experience. Leech Industries takes responsibility for nearly every step of production, from the moment we receive a quote to the final delivery. From there, we become the single point of contact for our customers, streamlining production so things run as smoothly as possible.

Leech Industries can handle projects of all sizes. We have experience with the simplest brackets being used in household applications through complex, advanced parts being used in the industrial space, and everything in between.

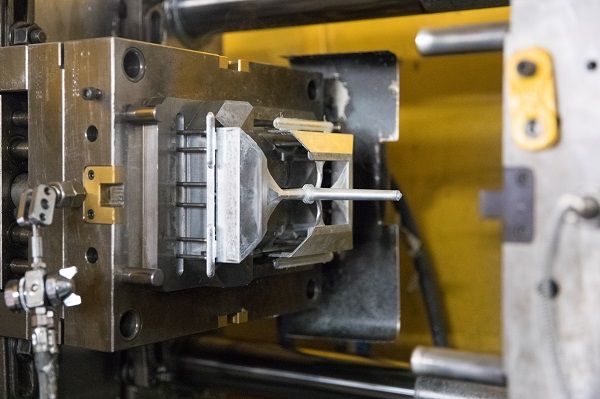

Zinc die casting, the process of injecting molten zinc into a mold, is one of the most productive ways we create unique, complex parts at Leech Industries.

The steps we deploy to produce high-quality zinc die cast components include:

Leech Industries offers a wide range of zinc alloys that can produce high-quality results across multiple industries. Our AS9100 and ISO 9001:2015 certifications give us the quality fundamentals needed to satisfy even our most stringent customer requirements.

Due to its ability to be coated and finished in various ways, zinc is an excellent choice for the following applications:

Zinc’s high-strength and durability make it suitable for use in die-cast toys and games, such as action figures and model cars, airplanes and trains. The substance is non-toxic, making it a safe option for young children. Zinc die casting allows for the cost-effective mass production of toy and game components, which is crucial for keeping manufacturing costs down in the competitive toy industry.

As a non-toxic, corrosion-resistant metal, zinc is commonly used in food and beverage applications, particularly frying pans, pots and utensils. In addition, zinc has a high coefficient of thermal conductivity that allows for even heat distribution, reducing the risk of hot spots while cooking.

Zinc’s properties, namely its strength, durability and corrosion resistance, make it a suitable choice for automotive parts and engine components. Zinc die casting provides exceptional precision, ensuring that automotive parts meet strict quality control and safety standards.

Zinc works nicely in harsh environments due to its corrosion resistance, making it a popular material choice for outdoor electrical connections and enclosures. Zinc alloys also exhibit great electrical conductivity, which is crucial for connectors, terminals and other components. Due to zinc’s good thermal conductivity, it is advantageous in applications that require heat dissipation, such as heat sinks and electrical enclosures.

Today’s consumers want products that are lightweight, cost-effective and sleek in appearance. Zinc alloys are relatively lightweight, so they are commonly used in portable goods such as cell phone cases and laptop frames. Zinc also produces parts with a smooth surface finish, reducing the need for secondary finishing processes that could increase costs and lead times.

Zinc is an incredibly corrosion-resistant material, especially with additional coatings. This is why many durable outdoor products use zinc die cast components, including:

Zinc is the most frequently used material for sacrificial anodes, as its dissimilar makeup to the steel used in hull and drive systems allows the more reactive zinc to corrode and rust first. This is a cost-effective solution, as zinc is significantly cheaper than steel. Zinc components also exhibit excellent corrosion resistance, particularly in saltwater environments.

In roofing and construction, zinc caps are commonly placed over steel screws or fasteners that are used to attach metal roofing sheets or panels to a building’s structure. These caps contribute to the longevity and durability of building projects; that’s why durable, corrosion-resistant zinc is the choice material for protecting steel screws from the elements.