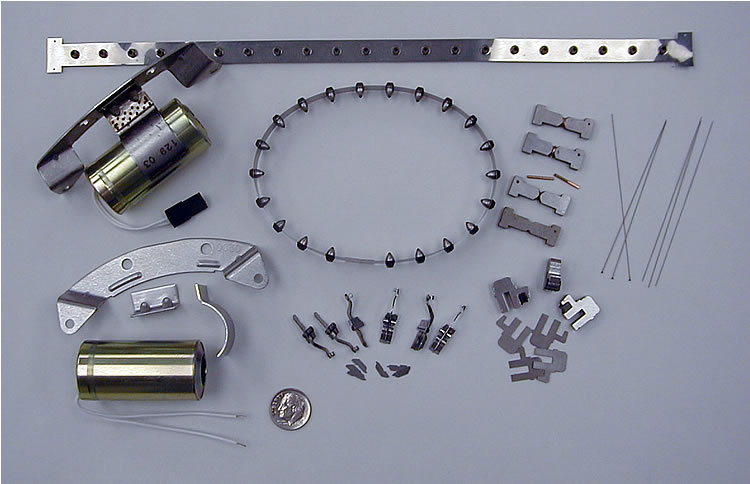

At Leech Industries, we can laser weld a variety of metals. We can provide this service on parts we make, such as those from our metal stamping department, or components you supply. Our CNC lasers produce accurate welding repeatability.

After laser welding, we can even assemble your parts into sub-assemblies or finished assemblies according to your specified processes.

The team at Leech can produce custom fixtures to hold and position components being laser welded in specific and/or complex configurations. This capability ensures precise alignment and stability during the welding process, resulting in consistent, accurate welds, particularly when working with intricate or unique workpieces.

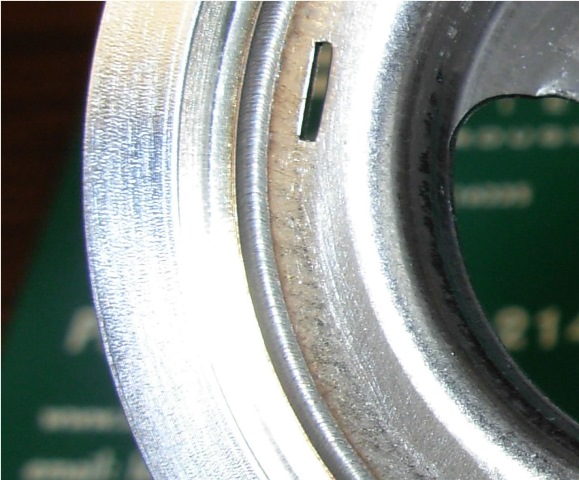

Our welding team has access to turn tables that rotate the workpiece during laser welding. These devices allow us to weld multiple angles without manually repositioning the part, saving time and improving the accuracy of the weld.

We utilize orbital welding techniques for circular or cylindrical welds for enhanced efficiency and precision.

Leech can provide a range of quantities, from one-off prototype jobs to large-scale projects of tens of thousands of components. Our versatility in project sizes makes us a helpful partner to OEMs of all demands and requirements.

In addition to providing prototype to production-level volumes, we can laser weld tiny parts of only .030” to large parts up to 25”. How we weld these component sizes varies, so if you have any questions regarding specifics, don’t hesitate to contact us.

Our catchphrase is “Leave it to Leech.” Leech Industries offers turnkey services, supporting customers every step of the way. From prototype to production, we offer full-service manufacturing solutions of the highest quality.

Leech Industries can laser weld the following material types: