At Leech Industries, we pride ourselves on the capabilities that allow us to provide full-service manufacturing solutions to our customers. As a one-stop shop, we offer assembly services to complete products in-house.

We offer a range of assembly services, including turnkey finished assemblies or assembly of customer-supplied processes and consigned parts.

At Leech Industries, we provide the following assembly services:

In some instances, Leech sources parts and hardware from outside vendors, saving our customers some of the legwork. We work with a reliable network of vendors for both standard and specialized components to add to our assemblies.

Most often, we make the components that go into our assemblies. Sourcing line replaceable units (LRUs) from Leech can…

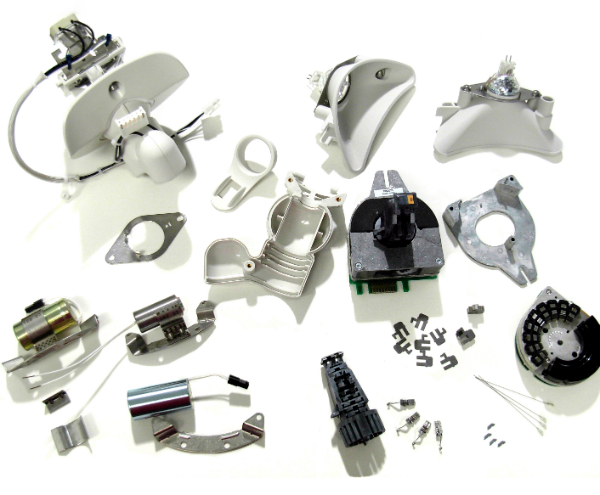

The Leech team is well-versed in electro-mechanical assembly, a process that creates complex systems that involve both electrical and mechanical components. Our strong expertise in electro-mechanical assembly makes us a well-suited partner for your specific production needs.

We can handle a variety of electro-mechanical assemblies, including:

Because we perform several precision machining services in-house, we can offer unique solutions based on our customers’ specific needs. Additionally, we perform our own in-depth inspection and testing services on our assembled components to ensure they meet specifications.

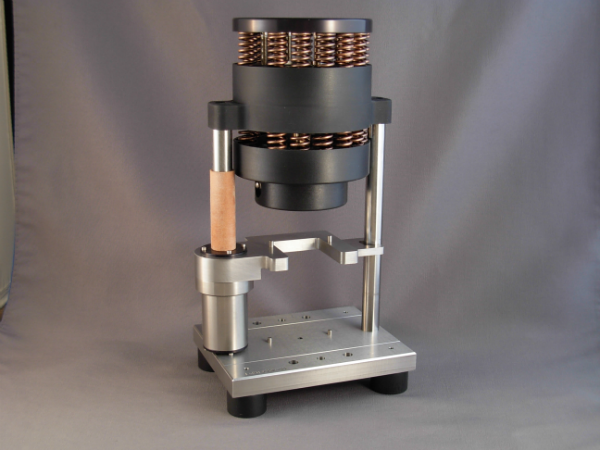

As an extension of our top-notch facilities, Leech Industries has a 550-square-foot Class 10,000 cleanroom to perform all electro-mechanical assemblies. This classification is beneficial in the following ways:

After the initial assembly, components often go through additional manufacturing processes to achieve specific functional or aesthetic requirements.

Our quality control team works in conjunction with our assembly team to perform the following testing procedures:

Break, pressure and other types of testing are fundamental steps in the manufacturing process that ensure products provide optimal performance and quality.